Daniel Giannetti

In this article…

Leather – An Overview

Leather is a highly durable and versatile material that has been a cornerstone of human civilization for thousands of years. The earliest recorded use of tanned and processed animal hides for leather can be traced back to 7000 years ago. However, in recent years the environmental and ethical concerns surrounding its production have been put to light. Due to these concerns, alternatives to leather and leather-making processes have been proposed. One of these emerging alternatives is the use of biosynthetic leather, which utilizes cutting-edge biotechnology techniques to reduce the overall environmental footprint of leather while simultaneously mimicking its best qualities.

The Environmental Toll of Traditional Leather

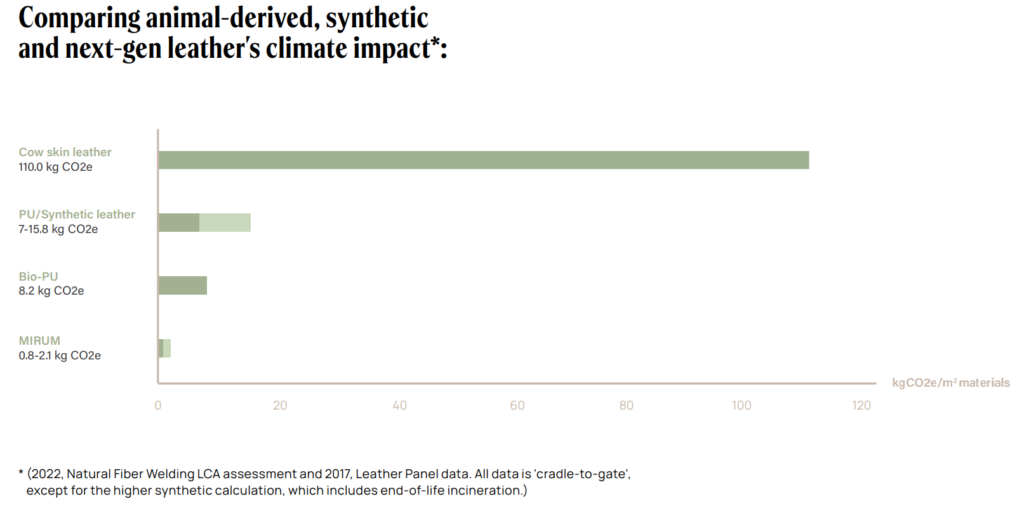

Traditional leather production involves the tanning of animal hides, a process often reliant on chromium-based treatments used in 80% of all tanneries. This method not only poses health risks but also contributes significantly to environmental pollution. As awareness of these impacts grows, both consumers and manufacturers are turning towards more sustainable practices. In a fantastic report by Collective Fashion Justice, they highlight many of these environmental effects. Especially the overall carbon footprint of leather production, which they illustrated in the graph below. Cow skin leather was identified as having a 13-fold increase in CO2 emissions over Bio-leather counterparts.

This collective shift in the societal perspective of leather has hastened the development of more effective alternatives.

The Biology of Leather

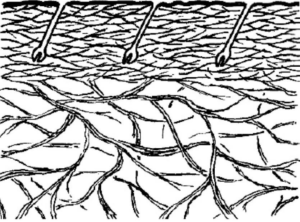

Leather is a biodegradable, durable, and resilient biomaterial made from treated animal hide. Its desirable properties stem from its structure, which is mainly comprised of fibrous woven collagen networks. These networks and their 3-dimensional interactions are strengthened via the formation of cross-links during the tanning process. Leather has a higher strength when compared to other fabrics due to this 3 dimensional structure of interwoven collagen matrixes This structure contributes directly to leather’s characteristic elasticity, vapor permeability, and durability.

Retrieved from “Comparison of the Technical Performance of Leather, Artificial Leather, and Trendy Alternatives” image depicts a stylized view of leather’s structure.

The Rise Of Bio-Synthetic Leather

Bio-synthetic leather represents a new frontier in sustainable fabric production. Utilizing advanced biotechnology, researchers have developed materials that offer the aesthetic and functional qualities of traditional leather while significantly reducing environmental impact. These bio-synthetic leathers mimic the tactility, durability, and resiliency of conventional leather though tend to fall short of matching this criteria exactly.

Here is a table summarizing some emerging bio-synthetic leather varieties.

The Science Behind Bio-Leathers

Bio-synthetic leathers aim to replicate the structure and properties of natural leather, which is made up of densely woven collagen fibres. In bio-leathers, materials such as chitin (in mycelium-based leather) or cellulose (in plant and bacterial derivatives) undergo processes to create a similar three-dimensional, crosslinked structure. This is being done currently, via processes with little environmental impact and non-toxic substituents!!

1. Mycelium-Based Leather

Mycelium, the vegetative part of fungi, consists of a network of hyphae that can be grown on various substrates to form leather-like materials. This type of bio-leather is not only biodegradable and compostable but can also be produced with a drastically lower carbon footprint. Structure and morphology are highly customisable as material characteristics are dependent on species, substrate, and feed type which is readily modifiable.

Mycelium-based leather is currently in production by the material innovation company Bolt Threads.

2. Bacterial Cellulose Leather

Cellulose is a polysaccharide composed of long chains of glucose molecules. Some bacteria strains naturally produce cellulose – commonly members of the genera Komagataeibacter. These bacteria produce cellulose pellicles that accumulate in their growth media and when dried form a material that provides tactile properties similar to that of finished leather. The growth of bacteria is conducted in entirely controlled conditions. Like mycelium-based leather, bacteria species have the potential to be selected/genetically engineered for more desirable properties during production and in the resultant product.

3. Plant Cellulose Leather

Cellulose is the main structural component of plant cell walls and is responsible for providing rigidity to the plant. It is the most abundant biopolymer on earth. Plant cellulose leather is developed by extracting the cellulose from plants and then mixing it with a bio-polymer to form a layered cellulose structure that mimics the properties of leather. This technique is also being adopted by biotechnology company Modern Meadow, creating a fabric similar to leather that can be improved and modified far more flexibly than conventional leather.

Modern Meadow’s website states that this biomaterial offers a “stronger and lighter” fabric when compared to traditional leather. We were not able to ascertain how this understanding had been reached (and subsequently, the accuracy) but it is an exciting prospect nonetheless.

Summary

Bio-synthetic leather represents a promising advance in the pursuit of a sustainable leather alternative. Conventional leather utilises hazardous chemicals in its production and contributes directly to environmental pollution. New bio-synthetic leather varieties have emerged to combat this. They attempt to mimic leather’s durability, tactility, and resiliency by processing analogues to leather’s main structural component – collagen. As we continue to innovate, the promise of a more sustainable and humane approach to one of our oldest materials is on the horizon. What a time to be alive!